Overview

Traditional fabric scanning methods present challenges like time-consuming processes and less accurate texture maps created manually through Adobe Photoshop. By integrating NunoX’s Premium Scanner and NunoX Cloud material editing software, companies can achieve high-definition texture maps, reduce product development time, and improve overall efficiency. This case study highlights the journey of NunoX with Shahi Exports.

Embracing New Technology

Shahi Exports is India’s largest apparel manufacturer and exporter, supplying fabrics to global brands. Known for their commitment to high quality, innovation, ethical operations, and environmental sustainability, they serve clients like Target, Walmart, Gap, and Decathlon. Recognizing the potential of more advanced technology to stay ahead in the industry, Shahi sought out alternatives for producing detailed fabric scans to meet client demands continually.

Navigating the Challenges in Traditional Fabric Scanning

Traditional Scanner Limitations:

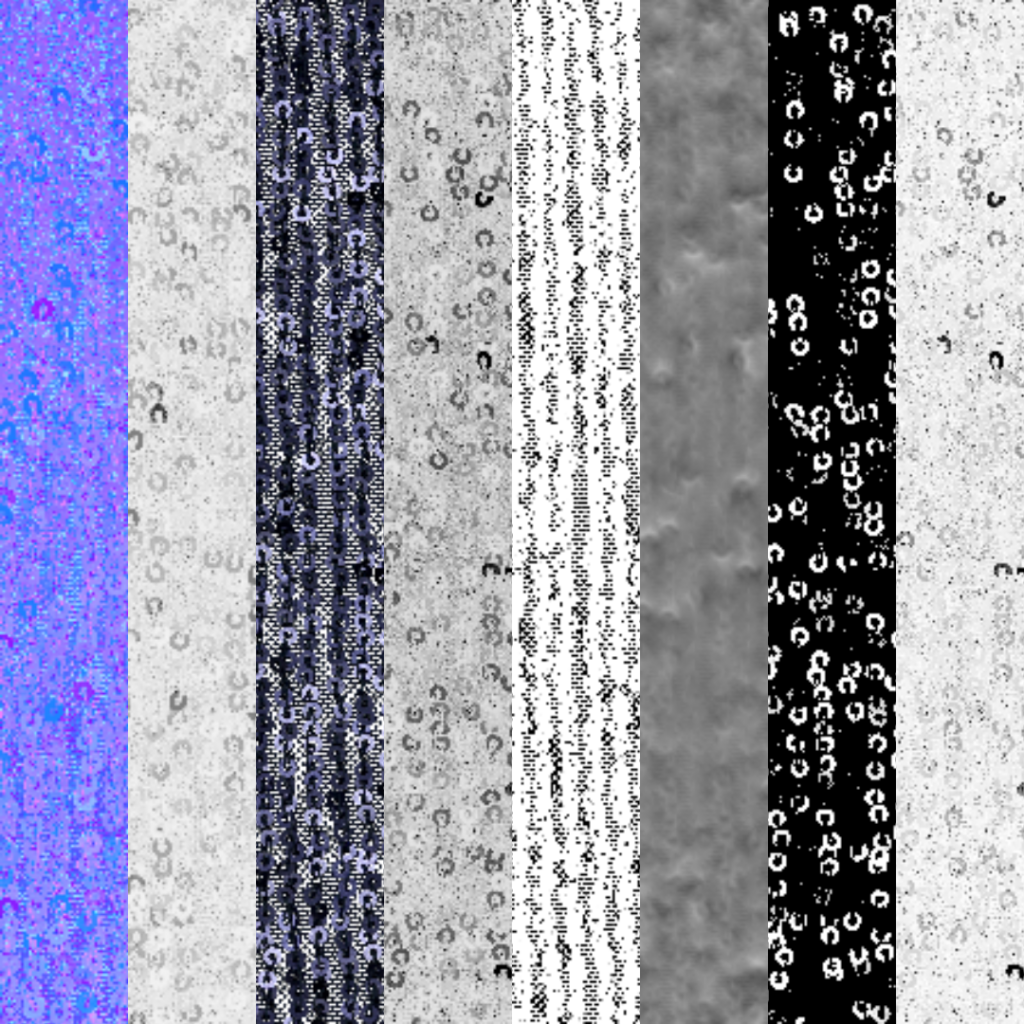

Scanners turn physical fabrics into virtual versions for digital design. Traditional scanners capture only one angle, lacking the necessary lighting to see detailed textures. It was especially difficult to get clear details for black and white fabric scans, prolonging product development time.

Manually Created Texture Maps:

Texture maps help designers visualize how fabrics look and move on digital garments.

These maps are essential to create a virtual touch-and-feel experience without physical samples. They add information like colors, wrinkles, shininess, and depth to enhance the design process and presentation. The design and development team used to manually create and edit texture maps in Adobe Photoshop. This process was time-consuming.

Defining Success in Fabric Digitization

When searching for a solution, the company focused on three key goals:

- Improve Scan Quality:

Achieve higher resolution and more accurate fabric scans to better represent fabric details. - Reduce Texture Map Creation Time:

Find software that automatically creates texture maps and stores digital fabric samples to save time and resources. - Enhance Efficiency:

Improve overall efficiency in the fabric digitization process, from scanning to sharing samples on garments with buyers.

Integrating NunoX: A Leap Forward in Fabric Digitization

NunoX’s Premium Scanner helps Shahi capture fabric images from multiple angles with professional lighting, making issues with black and white fabrics a problem of the past. A 3D digital fabric replica, or “digital twin,” is created in minutes with downloadable texture maps compatible with popular design software. These texture maps provide accurate textures for client garment samples.

Read more: How Digital Twins Are Disrupting the Fashion Industry

With the support of NunoX’s customer service team, Shahi can quickly integrate the Premium Scanner and Cloud platform into their digital product development workflow. Instead of taking weeks, it now only takes a few days to go from fabric scan to garment sample.

NunoX Cloud’s shareable link via QR code feature proved particularly useful for companies collaborating with clients. Clients can scan the QR code to view the fabric used on the garment sample, enhancing their engagement in the product development process and providing firm confirmation that the product is on the right track.

The client expressed satisfaction with the digital samples, highlighting the improved quality and efficiency of completing proposals.

Measurable Benefits with NunoX Solutions

After integrating NunoX’s solution into their workflow, Shahi is producing accurate and high-quality digital fabric texture maps faster than before. The time required to create digital garment samples was reduced from several weeks to just 2-3 days, significantly accelerating the product development cycle. This integration has not only improved their internal processes but also elevated the output for their global clientele, ensuring that they produce quality products for their clients.

NunoX’s user-friendly system allows designers to operate it with minimal training, thus increasing productivity and reducing reliance on specialized skills.

The Road Ahead: Enhancing Capabilities with NunoX

Overall, NunoX solutions transform any company’s fabric digitization workflow in 3 key ways:

- Automatically create high-resolution texture maps.

- Reduce garment sample creation from several weeks to 2-3 days.

- Easily share fabrics for clients to view via a shareable link.

This allows companies to meet buyers’ needs more effectively and maintain their competitive edge. Shahi Exports plans to continue using NunoX’s solutions for future projects. They are also looking forward to exploring additional NunoX features, such as AI Physics to simulate fabric drape, to enhance their processes.

Learn more about NunoX and the Premium Scanner here