Technology is impacting every product lifecycle stage, from idea conception to final production. A key part of this shift is the use of digital twins—virtual 3D replicas of physical objects, processes, or systems that are continuously updated with real-time data. This technology allows manufacturers to simulate and test processes digitally, enabling better decision-making before moving to physical production.

In the fashion industry, digital twins offer new ways for manufacturers and suppliers to reimagine business processes. Digital textile twins—virtual versions of fabrics and garments—help streamline product development, improve sustainability, and reduce waste.

The fashion industry is responsible for producing 92 million tons of textile waste and contributing to 20% of global clean water pollution. Adopting innovative technologies like digital twins is crucial to reduce the industry’s environmental impact and drive sustainability.

What are Digital Twins?

A digital twin is a virtual model of a physical object, process, or system that continuously updates based on real-world data.

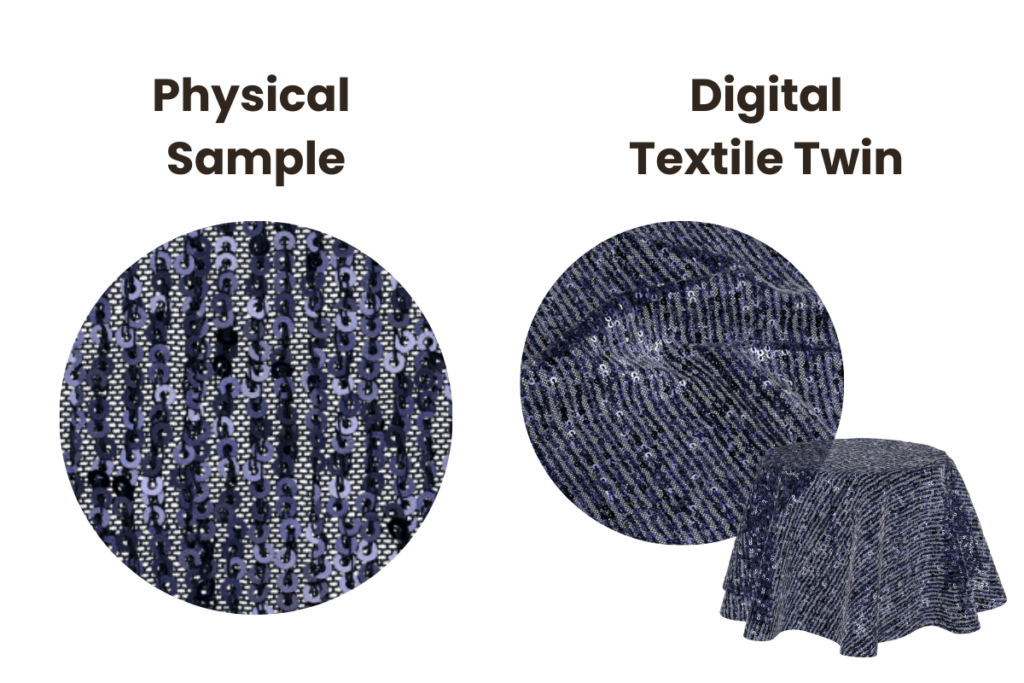

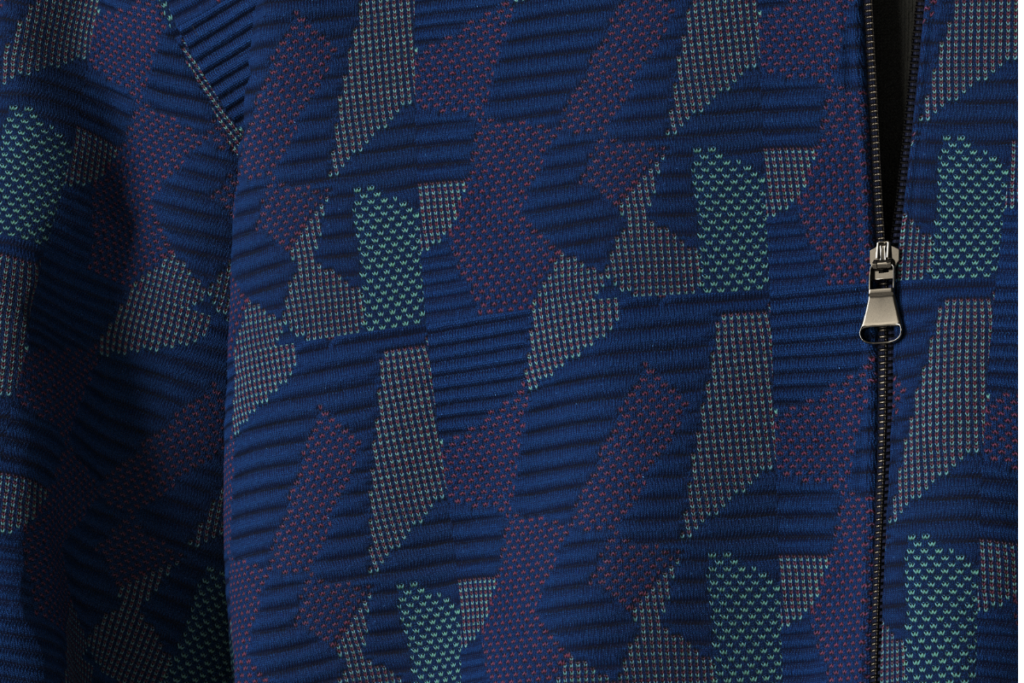

Digital twins are revolutionizing how brands develop and test products in the fashion industry, providing new opportunities for innovation and sustainability. Digital textile twins replicate physical materials like textiles, garments, and accessories. Using technologies such as artificial intelligence (AI), machine learning, 3D modeling, and the Internet of Things (IoT), these digital replicas allow manufacturers and designers to track, analyze, and simulate the behavior of materials in real-time. Digital textile twins can be created by using material digitization tools like the NunoX Premium Scanner or a smartphone camera.

Read More: Fabric Scanners: Essential Guide to the Best Material Digitization Tool 2024

For example, designers can create 3D digital fabrics that replicate properties like texture, drape, and color. These can then be used to test virtual prototypes before moving to physical samples. Similarly, fabric suppliers can offer vast digital swatch libraries, allowing customers to choose materials without needing physical samples. This digital-first approach lets companies visualize, test, and modify designs at every stage of production, improving efficiency and reducing waste.

Diverse Applications of Digital Twins

1. Create Visual Content for Marketing and Sales

Digital twins enable brands to create hyper-realistic 3D renderings of upcoming designs for use in marketing and sales materials. This can be done long before physical products are produced, allowing companies to test consumer interest through digital campaigns. These 3D models can be used for product images on e-commerce platforms, social media, and advertisements, reducing the need for costly in-person photoshoots.

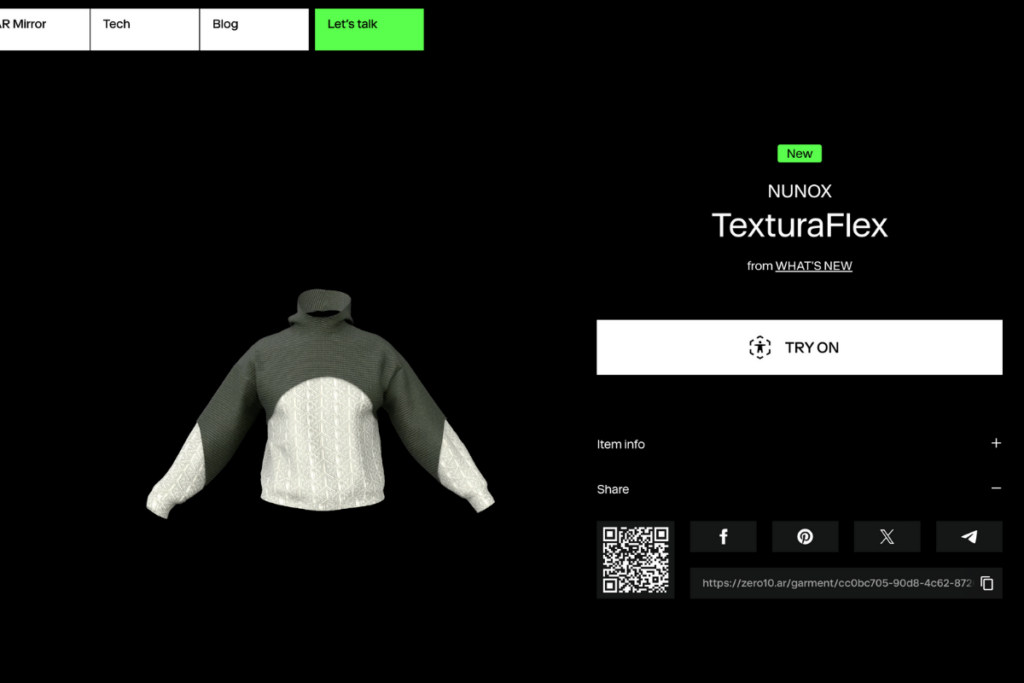

2. Digital Try-Ons with Augmented Reality

By leveraging digital textile twins and augmented reality (AR), brands can offer virtual try-on experiences. Consumers can use AR apps, like Zero10, to visualize how a garment will look and fit on their body before making a purchase. This enhances the shopping experience and reduces returns, benefiting both retailers and the environment.

3. On-Demand Production

Digital twins open the door to on-demand production, allowing manufacturers to create customizable, made-to-order garments. This approach helps minimize excess inventory and reduces the waste associated with mass production. It also aligns with consumers’ growing demand for personalized products, allowing brands to cater to individual preferences while maintaining efficiency.

The Benefits of Digital Twins in Fashion Product Development

1. Organizing Digital Libraries and Enhancing Collaboration

Digital textile twins enable fashion companies to create and maintain a searchable digital fabric library. This library allows designers to easily find specific materials, access detailed information about fabric properties, and reuse digital versions for future projects—all without needing physical swatches on hand. This centralization makes collaboration more efficient, allowing design teams, manufacturers, and suppliers to work seamlessly across locations.

For fabric suppliers, digitizing their entire inventory allows them to sell material online globally, making it easier for clients to access fabrics from anywhere. This digital approach streamlines processes and reduces the reliance on physical materials, speeding up decision-making.

2. Rapid Virtual Prototyping

Virtual prototyping with digital fabrics gives designers more creative freedom. They can quickly modify designs and experiment with different textures, patterns, and colors—all in a virtual environment. This rapid prototyping significantly accelerates product development, reducing time to market and minimizing the amount of physical waste created.

3. Reduced Costs

With digital textile twins, each design iteration can be completed digitally, reducing the need for physical fabric swatches or prototypes until the final designs. By cutting down on physical samples, companies save on material and shipping costs and reduce waste. Resources that would have been spent on physical samples can be reallocated to other business areas.

4. Enhance Collaboration Across Teams

Digital fabrics also make collaboration more fluid. Teams spread across different locations can access and share digital assets in real time. Designers, manufacturers, and clients can view the same digital textile twins, provide feedback, and make adjustments instantly, streamlining approval processes and reducing project timelines. This real-time collaboration ensures everyone works with up-to-date models, reducing miscommunication and errors.

Digital Twins Support Sustainability Initiatives

Sustainability has become a core priority in the fashion industry, and digital textile twins offer a powerful tool to minimize waste and improve resource efficiency. Traditional fashion production involves significant fabric waste, particularly during the sampling phase. Digital fabrics address these challenges by enabling virtual testing and simulations, reducing the need for excessive physical samples.

1. Minimize Fabric Waste

Traditionally, designers need numerous physical samples to perfect a garment’s fit, fabric, and design. This process leads to considerable fabric waste. Digital textile twins allow much of this development to occur in a virtual environment, drastically reducing the number of physical samples needed. By shifting most of the design process to the digital realm, companies can lower fabric consumption and reduce their overall environmental impact.

While physical samples still play an essential role in ensuring that the final product matches the tactile feel of the digital model, the goal of digital twins is to reduce, rather than eliminate, physical samples.

2. Sustainable Production

In addition to cutting fabric waste, digital textile twins help manufacturers refine production processes. By simulating various production scenarios, companies can optimize energy usage, reduce emissions, and conserve water. The ability to test processes digitally before committing to physical production leads to more sustainable manufacturing practices and improved resource efficiency.

3. Optimizing Material Usage

Digital fabrics allow manufacturers to optimize material usage by providing precise insights into how much fabric is required for a specific design. By testing fabric layouts and garment constructions digitally, companies can make more informed decisions that help them order only what is necessary, thus reducing production costs and minimizing excess material.

Challenges in Implementing Digital Twins

1. Technical and Operational Barriers

The integration of digital twins requires significant investment in technological infrastructure, such as 3D scanning tools, AI-driven analytics, and IoT devices. For smaller businesses, these upfront costs can be a barrier. However, overcoming these challenges early can provide a competitive edge as digital materials become the industry standard.

Actionable Steps:

- Start with a small pilot project, focusing on digitizing a single garment or product line.

- Leverage existing infrastructure by integrating digital twin tools with current systems.

- Consider outsourcing to experts who can help implement best practices for digital workflows.

2. Complex & Difficult-to-Use Software

The perceived complexity of digital twin technology can be intimidating for teams accustomed to traditional methods. However, as software becomes more user-friendly, with tutorials and support resources available, this learning curve is becoming less steep.

Actionable Steps:

- Invest in comprehensive training to quickly get teams up to speed.

- Assign digital champions to become internal experts who can assist other team members.

- Use intuitive, AI-powered software like NunoX Cloud to minimize technical complexity.

3. Unclear Immediate Benefits of Using Digital Twins

The return on investment (ROI) from digital twin implementation may not be immediately visible, making it harder to justify the initial cost. However, much like investing in new equipment, the long-term benefits include faster design cycles, reduced waste, and greater operational efficiency.

Actionable Steps:

- Set clear, measurable goals, such as reducing sample production costs or speeding up design timelines.

- Focus on quick wins early on to demonstrate the technology’s potential to stakeholders.

- Communicate the long-term value of digital transformation, emphasizing sustainability and improved processes.

The Future of Digital Twins in the Fashion Industry

Manufacturing Processes

Digital textile twins will continue to streamline production and make on-demand manufacturing a reality. Brands are able to produce custom-fit garments with minimal waste, shortening lead times and reducing excess inventory. As digital twins become more advanced, manufacturers can optimize material usage, enhance quality control, and quickly respond to market trends, all while minimizing the environmental impact of traditional production methods.

End Customer Experience

For consumers, digital twins will transform the shopping experience. Virtual fashion will enable brands to offer fully digital clothing collections for gaming platforms and social media, allowing customers to engage with fashion in entirely new ways. Additionally, virtual try-ons using AR will become more advanced, providing customers with personalized, interactive shopping experiences that increase confidence in their purchasing decisions.

What’s Next: Digitizing your Materials

Embrace the future of digital creation and effortlessly digitize your materials with NunoX. As digital twins and virtual workflows become standard practice in the industry, digitizing your fabrics enables you to work faster, more efficiently, and more sustainably.

With NunoX, you can:

- Create highly accurate 3D fabric swatches that replicate your fabric’s texture, drape, and color.

- Store and organize your digital materials in a searchable library for instant access.

- Share your digital fabrics effortlessly across teams

- Utilize AI features to edit fabrics even faster.

- Design apparel and accessories all in one cloud platform

Digitize your materials today with NunoX and lead the way in digital fashion innovation.

Visit the NunoX website to get started.