Danish bespoke suit maker, Made-to-Fit, set out to improve their the tailoring process by utilizing state-of-the-art body scans. The business was having trouble maintaining consistency and precision in measurements between two stores, so it looked for a way to improve operations and differentiate itself in a competitive market.

Accuracy Problem

Christian Lydersen, CEO and founder of Made-to-Fit noticed that measuring accuracy presented a difficult hurdle when he couldn’t be at two stores at the same time. Manual measurements taken at his stores were prone to errors, which resulted in returns and problems with fit. Even with a skilled tailor and consistent subjects, slight variations in measurements can naturally occur. It’s all part of the intricate process of tailoring, where every detail matters. For Made to Fit, it became critical to find a system that could deliver accurate and consistent measurements. According to one survey of brick-and-mortar stores, it is estimated that returns reduce the bottom line of a store by 28.9%.

Body Scans as a High Tech Solution

3D body scanners are designed to capture your entire body in 3D through a body scan. A 3D model of your body shape is created with accurate data, including body measurements and landmarks. Body scans take only 3 seconds to capture all of this data, accelerating the measurement procedure while standardizing measurement capture. Two Scanatic 360 Body Scanners from TG3D were integrated into Made-to-Fit fitting rooms in Copenhagen and Jutland.

The integration of 3D body scanners marked a big change for Made to Fit. In addition to giving precise body measurements, these scanners expedited the fitting procedure by lowering the need for hand measurements. This meant they could measure more people and focus on the craftsmanship of creating the perfect suit for their clients. By doing away with inconsistent manual measurements, the scanners offered a uniform method of tailoring.

The Scanatic 360 Body Scanner in one of Made-to-Fit’s stores.

Customer Perception to Body Scans

Made to Fit’s clients welcomed the 3D body scanning process, considering it a proficient and effective means of acquiring precise measurements. “They’re shocked that doing a scan only takes three seconds,” Lydersen said. Notable for its speed, the 3-second body scan duration made for a seamless and easy fitting experience. Additionally, the body scans are private

Challenges and Takeaways

Lydersen acknowledged the time-saving potential of 3D body scanners while reflecting on their revolutionary impact and integration. “While the adoption of 3D body scanners saved time, there was a learning curve for tailors to fully trust the technology,” Lydersen said. Tailors need to get confidence in the technology.

Powerful Body Scan Software for Tailors

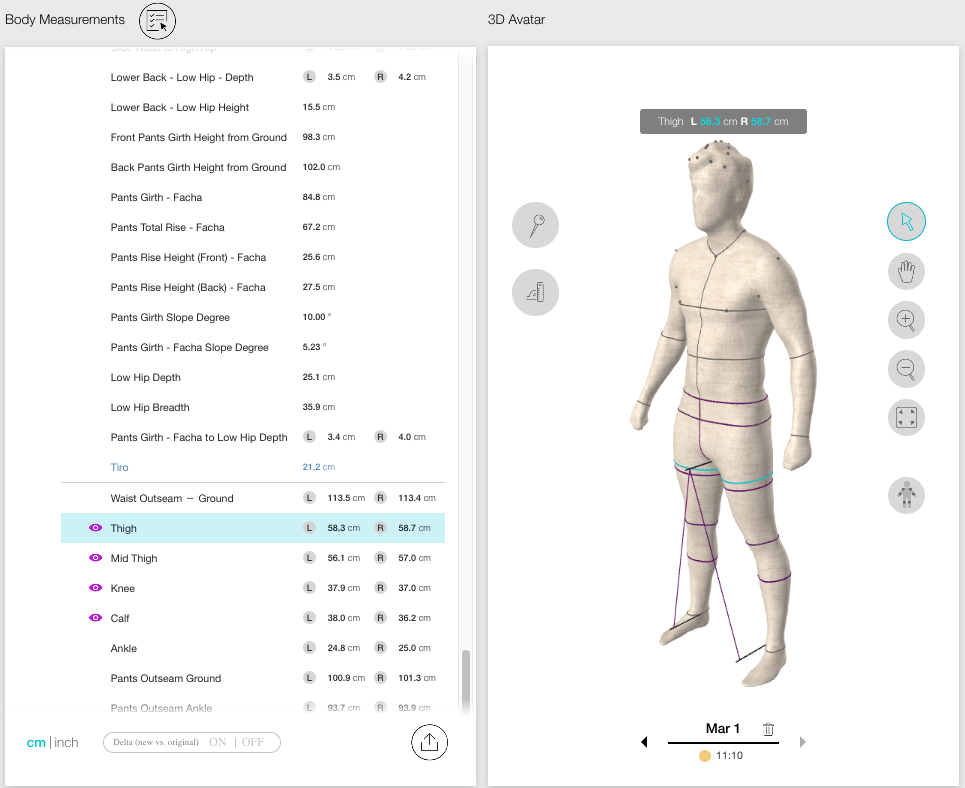

When body scans are uploaded to TG3D’s Tailor Software, the magic happens. AI is used to determine specific points in the body such as shoulder, chest, and neck.

The software also includes manual measurement tools which help the tailor analyze each measurement to ensure perfect fit.

The 3D avatar feature, allows them to visualize body forms long after their clients have left the store. This enables precise changes and customizations, ensuring satisfaction with each stitch.

Reactions to TG3D Studio

A major factor in Made to Fit’s success was TG3D Studio’s support. The robust customer support team’s availability and response made sure the technology was implemented smoothly. “They answer my questions at any time,” Lydersen said. The business valued TG3D Studio’s dedication to ongoing development and openness to their input.

Christian Lydersen, CEO and Founder of Made to Fit Denmark

Future Objectives

Made to Fit hopes that future technological developments would result in even more time savings and fewer changes. Made to Fit wants to improve consumer self-service and eventually achieve unattended scans by optimizing the customizing process.

In summary

The partnership between TG3D Studio and Made to Fit is a prime example of how adopting cutting-edge technology can transform established markets. With TG3D Studio providing the technology foundation, Made to Fit has established itself as a forerunner in the retail bespoke suit industry by emphasizing accuracy, uniformity, and client experience. The adventure continues, with an emphasis on maintaining an edge over industry trends and making constant improvements.